Transactional Purchasing for the Jobsite

If you ask the average project manager what the costs are on a given project, they can usually give you a number that's pretty close off the top of their head (or better yet, an accurate number from a cost report at their finger tips!). But if you ask the same project manager, how many transactions took place to add up to that cost, the answer you get is... crickets.

The frequency that the team is transacting with vendors isn't something we generally pay much attention to - and if you have a good system in place for purchasing, you really don't need to may much attention. The problem is that most companies DON'T have a good system for purchasing and there are very real costs that are increasing their overheads and eating their margins.

What is transactional purchasing?

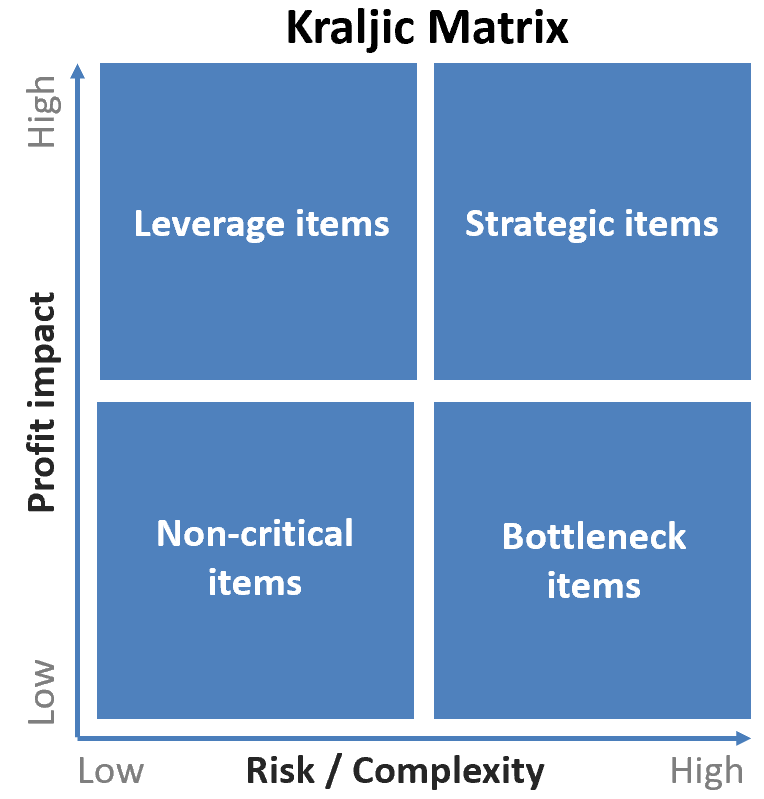

In 1983, Peter Kraljic published an article in the Harvard Business Review where he gave us this four-quadrant chart now known as the Kraljic matrix:

Transactional purchasing are all the things we buy in the lower left, "non-critical items" quadrant. Non-critical items have many sources of supply in abundant quantity, and in aggregate don't add up to a whole lot of total value. Things like safety supplies, lumber, and drinking water, all fall into this category.

As general contractors, when we think about costs that hit our jobs, we often go straight to subcontracts, labour, and the major material packages that add up to 90%+ of the total project costs. The last 5% are the transactional purchases, and because the value is so low, they are easy to forget about.

Here's the catch - transactional purchases are only 5% of your costs and 90% of your transactions!

But here's the catch - while they are only 5% of your costs, they represent 90% of your transactions! A mid-size general contractor with annual revenue of $100M will conduct thousands of transactions every year with their suppliers, and the median value of those transactions will be between around $400... this means half of the transactions of that company are less than $400!

Sure there's a bunch of piddly shit - why does that matter?

So why should you care? Great question! It matters because every one of those transactions takes TIME. The person doing the purchasing invests time working with the supplier to outline the order, they may or may not document the purchase, then someone in accounting has to deal with the supplier's invoice, and finally someone needs to pay what's owing.

Every step of the process takes time (costs money), and because we've already established its time spent buying something trivial, it means that is time that really should be invested into something more important on our project.

If you can reduce the total number of transactions, or if you can decrease the friction and time spent in the purchasing process, you will free up time for your people to do more productive, revenue generating tasks. And if done well, you might also get lower pricing on the cost of the goods you're buying (more on that later).

Reducing Purchasing Costs

There are two ways to win when discussing transactional purchasing: you can reduce the total number of purchases or reduce the time of a given step in the purchasing process. This is true if you use a central purchasing model, or a distributed field-level purchasing model. Here are some ideas to post a win for your construction business...

Grouping purchases

Have you ever been going through payables for a month and realized that someone bought something from the same vendor three days in a row? That's an example of a purchasing behaviour that is very expensive. With a bit of foresight, purchases can be combined into a single, larger purchase. This lowers the total number of transactions (win), makes the order more valuable to the supplier (win - more on that later), and reduces delivery fees (win - more on that later too).

Encourage the team to do regular, short-term lookahead schedules to forecast upcoming needs on site - Friday afternoons are great opportunities to set the following week up for success. Combine the next week lookahead with a quick inventory of levels of stock of your commonly used supplies and its easy to prepare a list of what you're likely to need. Fire off the order to your most trusted supplier(s), and the crew will have everything to be successful in a single delivery on Monday morning.

Grocery lists are also a good way to capture site needs and group purchases. Instruct the crew to make note of when consumables (screws, safety glasses, danger tape, drill bits, etc.) are running low - before they run out - on a common whiteboard. Check that list first before doing the inventory check and add those items to your order.

Standing Offers

Standing offers are another good way to reduce friction in the buying process. A standing offer is an agreement with a given vendor to supply certain goods at pre-negotiated prices. Establishing a standing offer with a key supplier provides cost certainty on a unit basis, and consolidates spending with the vendor for a specific category - which can lead to better overall pricing due to higher volumes.

Having a standing offer agreement in place and communicating that to the buyers on your team with the list of applicable items, allows the buyer to very quickly know where to go / who to call to place an order. It also allows your buyers to skip anytime negotiating or bartering on pricing which shaves time off the process.

Vending Machines

On larger projects, vending machines stocked with supplies can be excellent time savers. Suppliers will happily provide the machine and keep it stocked (software inside the machine will tell them when something is running low) - all you have to do is punch in what you need and you are only billed for what you use.

Using a vending machine means you don't have to place a call at all to the supplier (win), the supplier monitors inventory levels and groups restocking orders (win x2) and the pricing is already set using a standing offer agreement (win x3). It's literally all three of the above ideas in one!

Pickup vs. Delivery

Here's one that drives me nuts: the superintendent - the most expensive person on my project - is going to run over to a supplier's yard to pick something up... the justification: to save on a delivery charge. I hate to be the bearer of bad news, but that was the most expensive delivery we could have ordered.

Have things delivered - don't take time out of the day to pick them up.

If you are doing a good job of grouping orders, and you are a valued customer, many suppliers will waive the delivery charges if you ask them to.

As long as its not a rush, most suppliers servicing the construction industry at worst don't mind delivering, and at best prefer delivering because it allows them to optimize their yard schedules and maximize use of their delivery fleet. When you show up unannounced and expect them to drop everything to service you, you're actually making life harder for them than if you had just called in the order.

There are only two good reasons to pickup supplies instead of arranging a delivery:

- You're stopping in at Home Depot because its on the way home and the day is done.

- You have run out of a key material and the crew is standing around unable to work. Although if this is the case, there is a good chance some better planning would have avoided this issue.

Three Bids and A Buy (Wrong - Sole Source!)

Three bids and a buy is a saying you may have heard in the world of business purchasing. It implies that you call three different vendors to ask for the same basket of goods then compare pricing across the three suppliers and buy from the one with the best value.

In general, three bids and a buy is a good common sense rule of thumb, but when it comes to transactional purchasing it isn't a great idea. Remember, transactional purchases are high volume, low dollar value transactions. If you call three suppliers to get pricing on your sleeve of safety glasses you might find one who will sell them to you for $17 instead of $18, but you've spent far more than the difference making the phone calls in the first place (not to mention you just wasted the time of two other suppliers!).

The only way to win with transactional purchases is to get through them as quickly as possible and this means sole sourcing.

Call someone you know will have the product, buy it, and be done.

How Suppliers See You

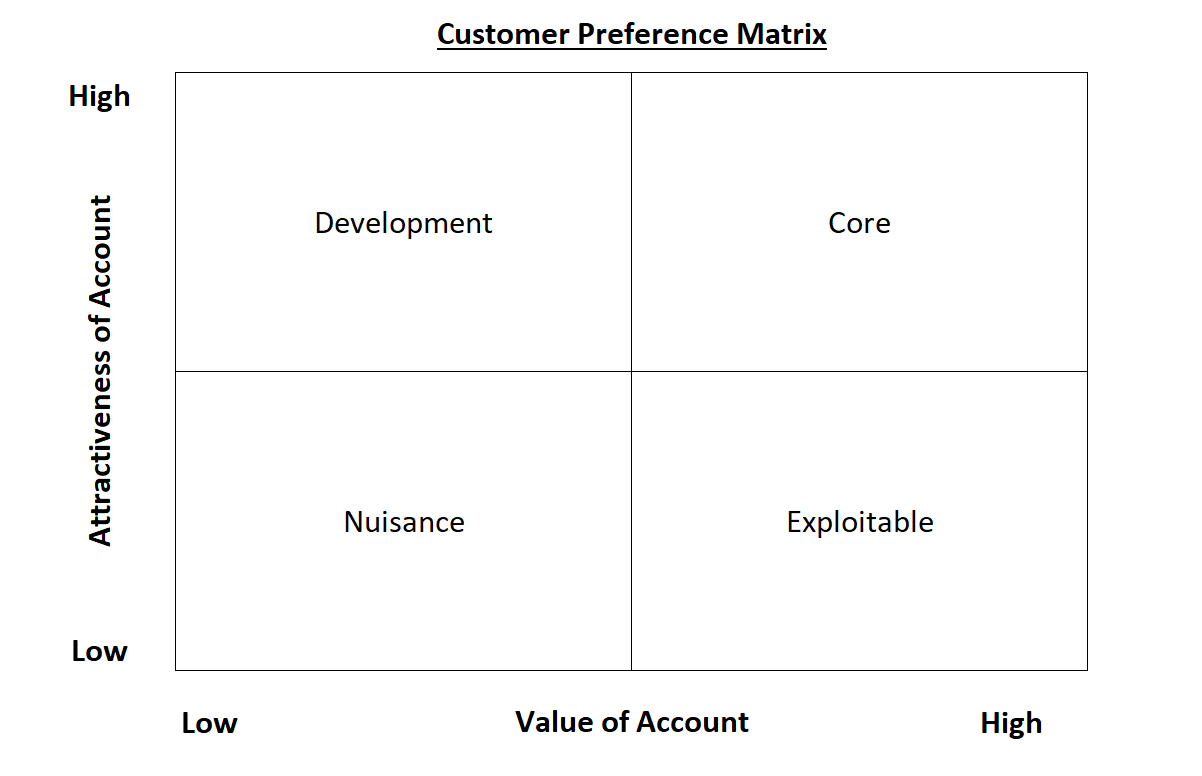

Earlier in this post, I talked about the Krajlic matrix - there is another, four quadrant matrix worth considering: the customer preference matrix.

This matrix applies to any business and their customers. Even if you haven't seen it before, you can probably slot your past or present customers into one of the quadrants. A customer that gives the odd job but grinds you down and then is a pain in the ass? Bottom left. The customer who gives you a ton of work and is easy going? Top right.

In the transactional purchasing world, you and your company are a customer to the supplier, and they will put you in one of the four quadrants. You want to be top right, core customer. The way to do that is to give them lots of dollar volume (making you high value), and make transacting as frictionless as possible (making you attractive).

The techniques listed above: grouping purchases, establishing standing offer agreements, using vending machines, having them deliver, and sole sourcing will improve your standing with suppliers.

Being a core customer means:

- In a pinch you rank ahead of everyone else, they will drop everything to support you

- Maximum discounts and best pricing is offered to you because they pass on the operational savings of working with an easy customer

- They will like you and be nice to you... and who doesn't want that?

It is often the case that smaller companies who are easier to work with (Development or Core quadrants) will get better pricing and service than the 800pound gorilla who is a pain (Exploitable quadrant).

This article, and all other articles published on this site represent my personal opinions and are protected by copyright laws.

When I link to products and services, those links may be affiliate links. If you click on any of those affiliate links and make a purchase, I earn a small commission. That commission is paid by the retailer at no cost to you.